KMS: Empowering Indian Enterprises to Seize the Billion-Dollar Market Opportunity

- 2026-01-08

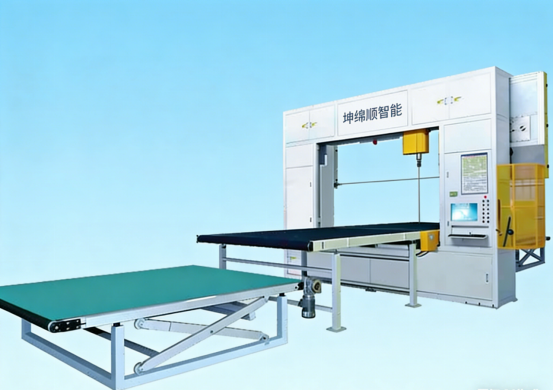

- HK & KMS Cutting Machine Manufacturers

- 169

1. A Vast and Growing Market

India's economic growth, urbanization, and the expanding middle class are driving sustained demand for foam products. Polyurethane demand is expected to exceed 565,000 tons, growing at a rapid annual rate of 10%–12%.

- Furniture & Home Living

As the largest demand sector, the market for mattresses, sofas, and other upholstered furniture continues to expand.

The growth of major local manufacturers, such as Sheela Foam (India's largest mattress maker), directly demonstrates the vitality of this sector. Consumers' pursuit of comfort, health, and customization is driving an urgent need for high-precision and diversified foam cutting solutions.

- Automotive Industry

With annual automobile production exceeding 4 million units, India is a major global automotive production hub. High-performance PU, PP, and other foams are essential for seating, interiors, and noise, vibration, and harshness (NVH) materials in every vehicle. - Packaging Industry

Accompanying the development of e-commerce and retail, the Indian packaging industry is growing at an astonishing rate of approximately 22% per year.

Protective packaging materials such as EPS (expanded polystyrene) and EPE (pearl cotton) are indispensable for electronics, fragile items, and cold-chain foods.

2. Why Choose Kunmianshun?

Choosing Kunmianshun means more than selecting a machine; it means choosing a strategic partner to propel your business toward an intelligent and efficient future.

We are committed to building your competitive edge through cutting-edge technology, superior cost-effectiveness, and reliable lifecycle services.

- Intelligent Nesting System

Our intelligent nesting system is the crystallization of algorithmic intelligence and industry experience, directly translating into profit advantages for you.

- Multi-Material & Multi-Process Capability

Beyond standard foam, our oscillating knife, wire cutter, ring knife, and rotary table systems can precisely cut high-resilience foam, memory foam, rigid foam, EVA, EPE pearl cotton, and even some composite materials.

Whether it is vertical cutting, bevel cutting (for sofa arms, car seat assembly), or multi-layer cutting, all can be easily achieved.

- Die-less Shaped Cutting

From receiving a customer's CAD drawing to completing the first sample cut, the process can be shortened to minutes.

This significantly accelerates product development and sampling speed, allowing you to seize market opportunities and easily handle small-batch, high-frequency customized orders.

- High-Efficiency & Stable Production

The core value of Kunmianshun equipment lies in its ability to create output stably and efficiently. - Robust Engineering Design

Targeting potential challenges in markets like India—such as voltage fluctuations, high temperatures, and dusty environments—we have reinforced the design of key electrical components and mechanical structures.

This ensures the equipment maintains excellent performance and longevity even under complex working conditions.

Summary

The market is open. Who you choose to partner with determines how high you can go. Kunmianshun looks forward to being your reliable partner, unlocking the India's billion-dollar market together.